High Throughput Array-Based Ice Adhesion Screening Apparatus (RFT-773)

Invention Summary

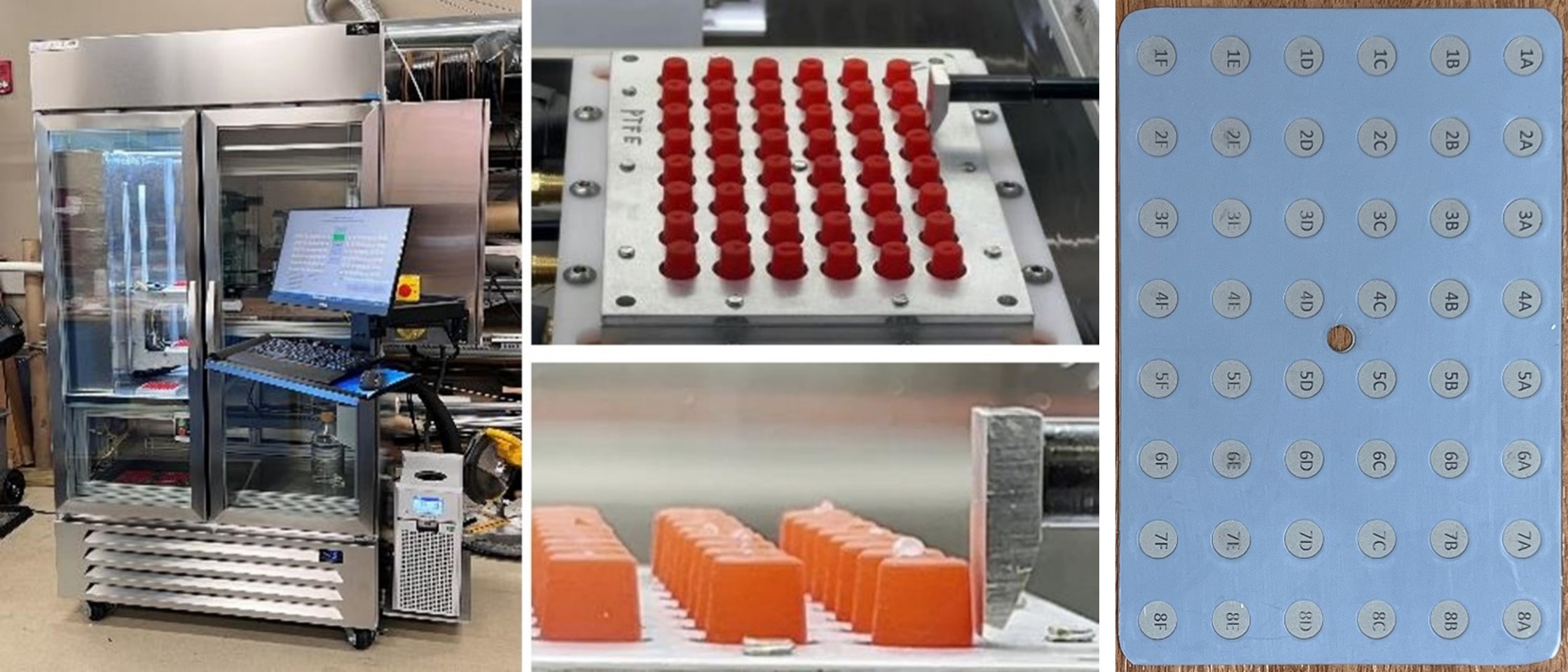

This machine measures ice adhesion by pushing a small ice mold frozen onto a coated test panel. Each panel contains 48 shallow wells, each holding 20 microliters of coating. The system features two actively cooled trays. Each tray holds a 48-well array plate. The chilled shelf ensures ice forms at the coating surface and grows upward. With 96 test sites per run and up to 288 per day, the apparatus enables rapid screening of hundreds of coating samples. Only the top-performing coatings are selected for full panel ice adhesion testing. The primary advantage is efficient testing of tiny quantities of anti-icing coatings.

This design uses flexible rubber ice molds clamped to the array plate to prevent leakage. Each run measures 96 unique coating samples automatically, giving high throughput. The control software finds the maximum force needed to remove the ice. Operators can review data before reports are generated. The sealed ice molds let the system melt and refreeze plates for automated, unattended operation. If needed, a fully coated panel can be tested instead of the array plate. This method provides up to 48 replicate measurements. The ice molds are also scalable in size.

High Throughput Array-Based Ice Adhesion Screening Apparatus

Benefits

- The research coating panel has been reduced to a small dot (1 of 48) on a metal panel. Only 20 microliters of coating material is needed to

fill the array plate wells. Compared to 10s of milliliters needed to coat a standard test panel

- The ice molds used in this apparatus are flexible rubber that are clamped to the plate to prevent water leakage.

- One run of the machine will automatically measure 96 unique coating samples for ice adhesion properties. This is high throughput

- The control software has an algorithm that detects the maximum force to push off the ice.

- The design of the sealed ice molds allows the system to go into a melt stage after a test, then refreeze the plate and run again. It does this all

in an automated, unattended manner.

- The molds are scalable and can be smaller or larger.

Applications

This apparatus is designed to provide a quick screening of several coating formulations for ice adhesion performance. The original design

requirement was that this test would be a go/no-go test for 100s of coating samples, allowing the researcher to eliminate those formulations that

do not perform well. Using this machine, such a determination can be made quickly with a minimal amount of material. As it turns out, the data

generated from this machine can rank coatings from good to bad, not just pass/fail.

Patent

This technology has a Patent pending and is available for licensing/partnering opportunities.

Contact

NDSU Research Foundation

info(at)ndsurf(dot)org

(701) 231-8173

NDSURF Tech Key

RFT, 773, RFT773

Inquire about this technology >