Silicone oil modified epoxy-siloxane coatings for ice and fouling-release applications (RFT691/RFT692)

Invention Summary

Ice accumulation on the surfaces of airplanes, ships, and wind turbines can hinder their proper functioning and pose safety risks. Traditional methods to prevent ice accretion, such as mechanical scraping, heating, or chemical treatments like anti-freeze or salt mixtures, are often time-consuming, inefficient, environmentally harmful, and costly.

As an alternative, passive prevention methods involving the application of coatings to delay ice formation or facilitate its removal have been explored. However, studies on various hydrophobic/ice-phobic surfaces reveal that these materials often lack durability, proper adhesion, or efficiency. Multi-layer coatings can provide both mechanical strength and ice-phobic properties, but they can also increase the cost and complexity of the process.

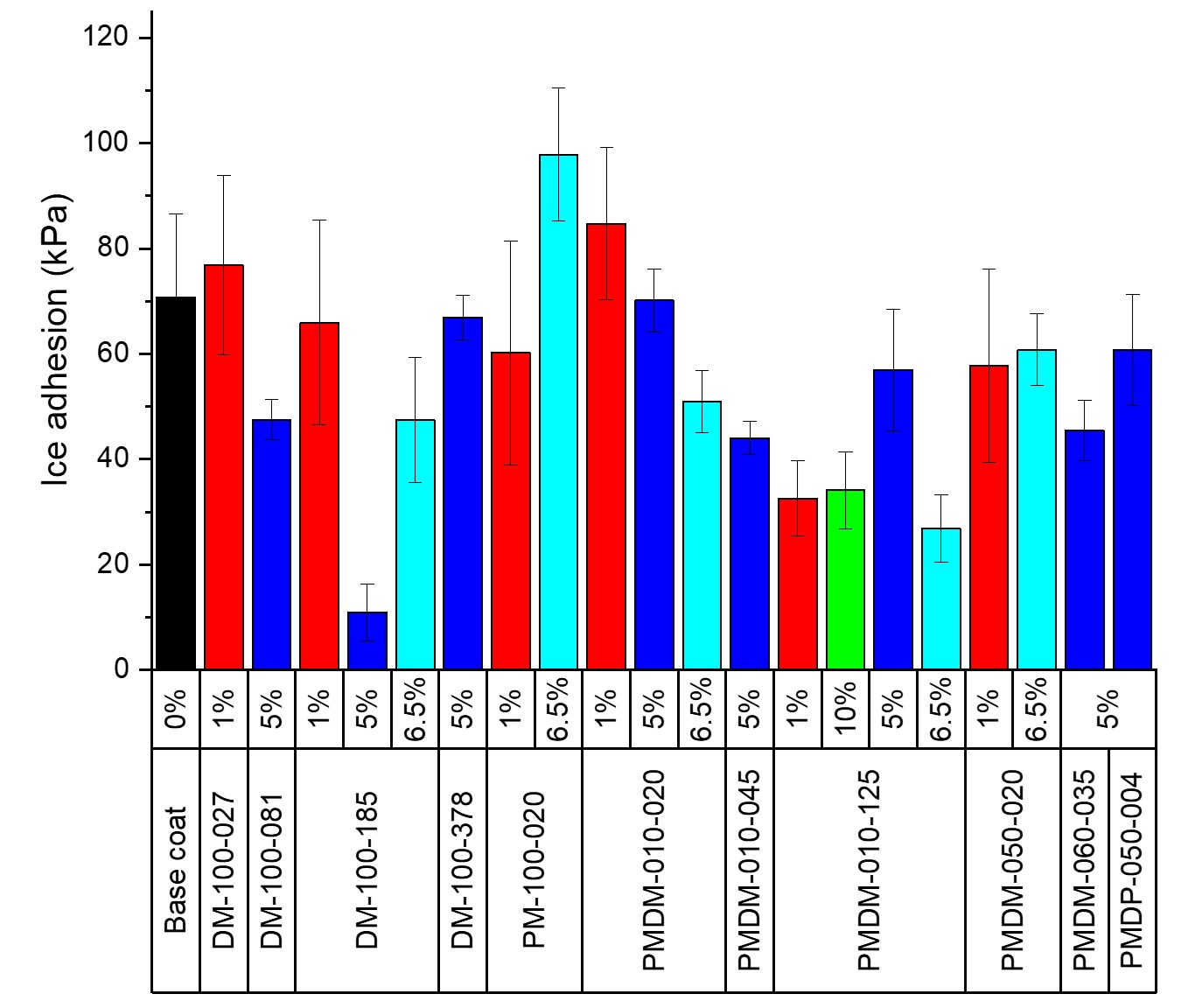

A single-component moisture-curable urea-siloxane coating for anti-icing applications. The urea linkage offers good adhesion and mechanical strength, while the siloxane chains provide durability and flexibility. Different percentages of silicone oil additives were used to study ice adhesion, contact angle, and surface morphology. The results showed that the presence of oil on the coating surface led to low ice adhesion strength and good mechanical properties. These coatings have potential applications in ice-shedding surfaces.

Applications

- Coatings for exterior infrastructure where the release of ice is required. Navy ships, power lines, exterior storage tanks,

etc.

Benefits

- Synergistic Use of Siloxane + Silicone Oils. Unlike most coatings that use either a siloxane or a silicone oil, this patent combines both in a curable system, enhancing mobility and surface migration of silicone oils, resulting in superior, persistent ice-phobicity and fouling resistance.

- Ambient-Temperature Curability Without Specialized Equipment. Many high-performance coatings require heat curing or UV treatment. This composition cures at room temperature (1–72 hours), a major advantage for field applications and cost-effective deployment.

- Sprayable, One-Part or Simple Multi-Part Formulation. Compared to complex multi-layer systems or coatings requiring pre-functionalized surfaces, this formulation is relatively simple to apply via spraying on various substrates (steel, wood, concrete, composites).

- Customizable Performance Through Additive Compatibility. The resin system allows the inclusion of other functional additives (anti-corrosion, pigments, fillers) without losing key surface properties—a flexibility not always present in fluorinated or hybrid ceramic coatings.

Patents

This technology is subject of issued US Patent US 2024/0343942 A1, and is available for licensing/partnering opportunities.

Contact

NDSU Research Foundation

info(at)ndsurf(dot)org

(701)231-8173

NDSURF Tech Key

RFT, 691, RFT691, 692, RFT692, 691/692

Inquire about this technology >